High-altitude special roof tile roll forming machine YX51-410-820

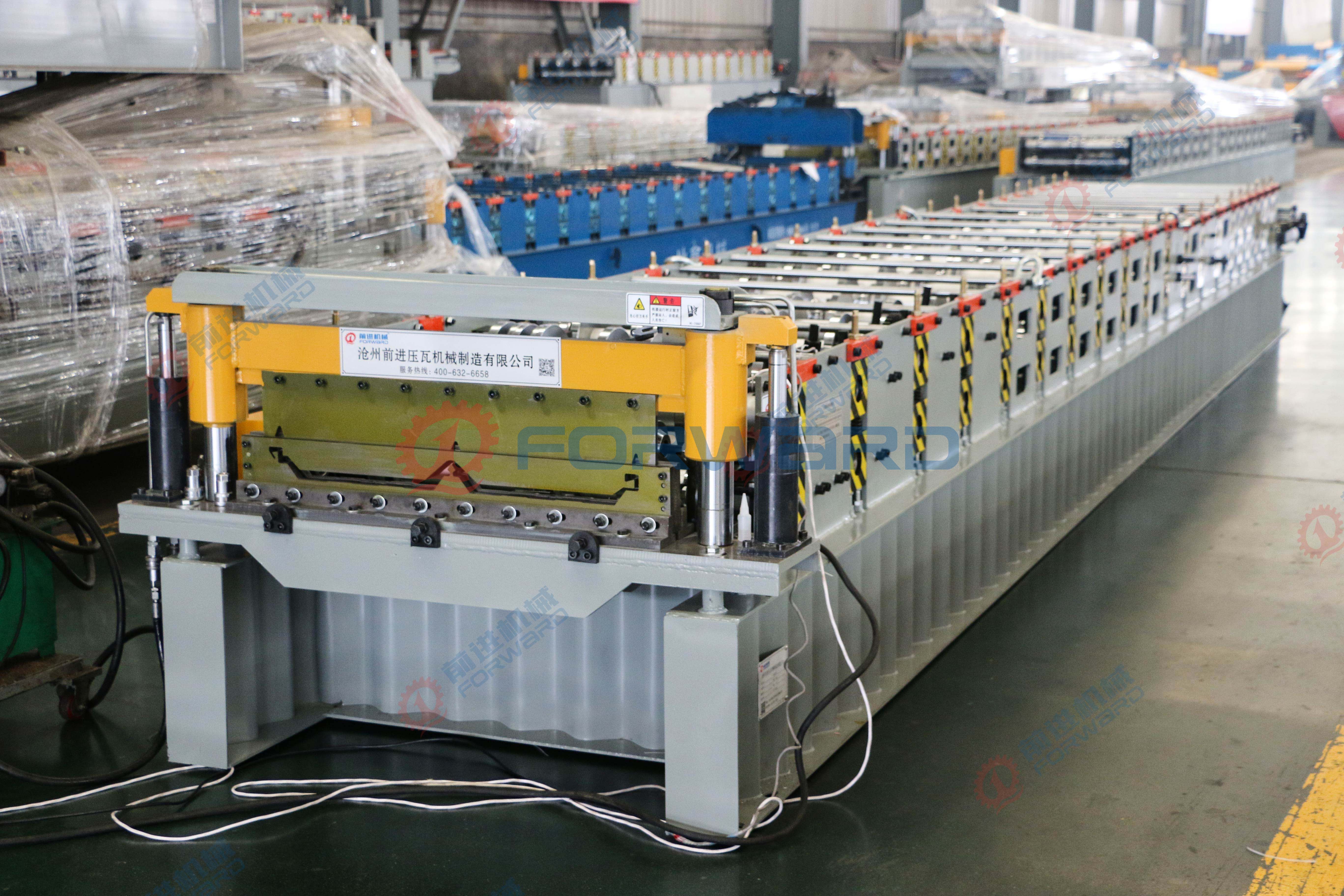

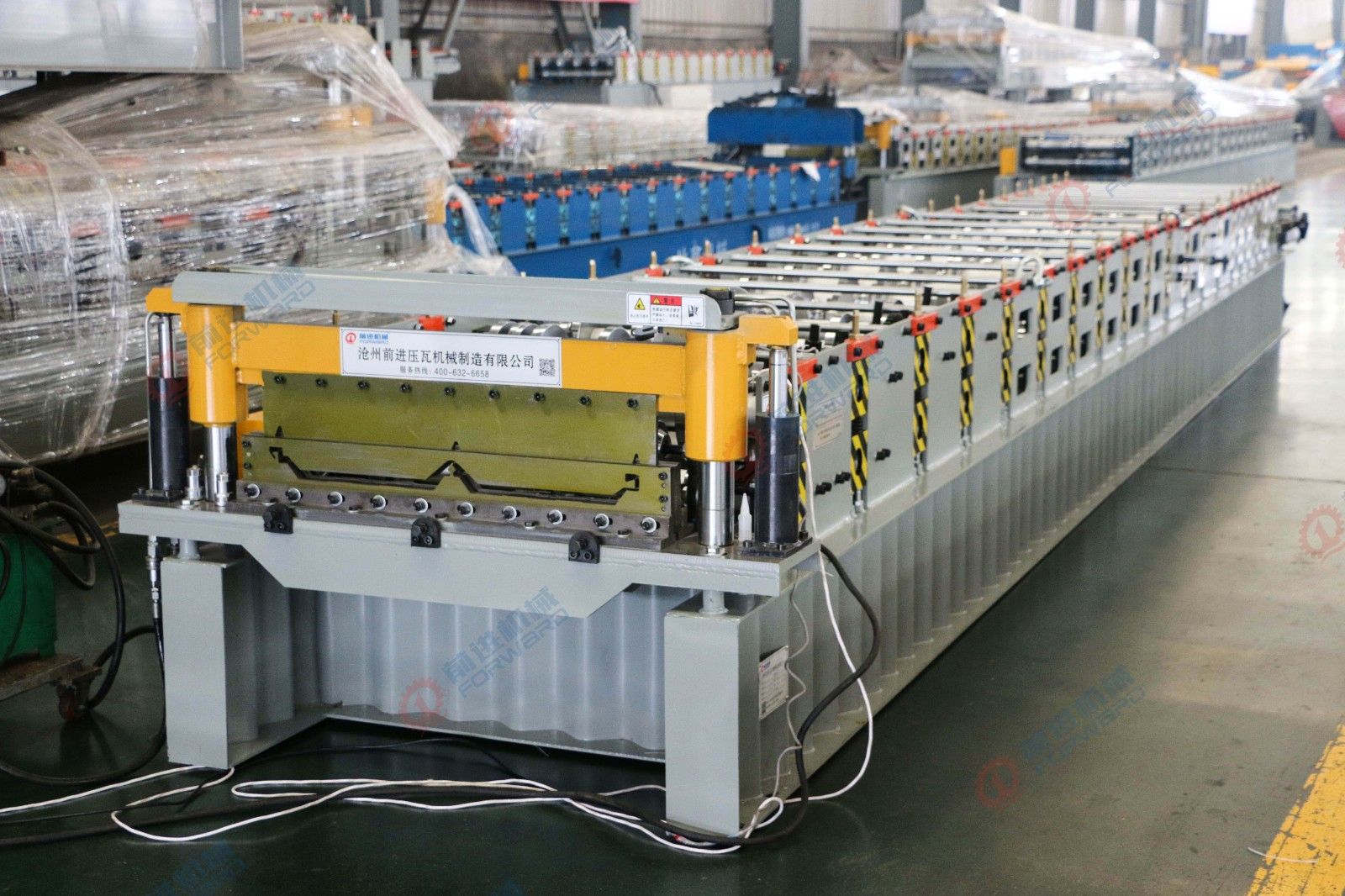

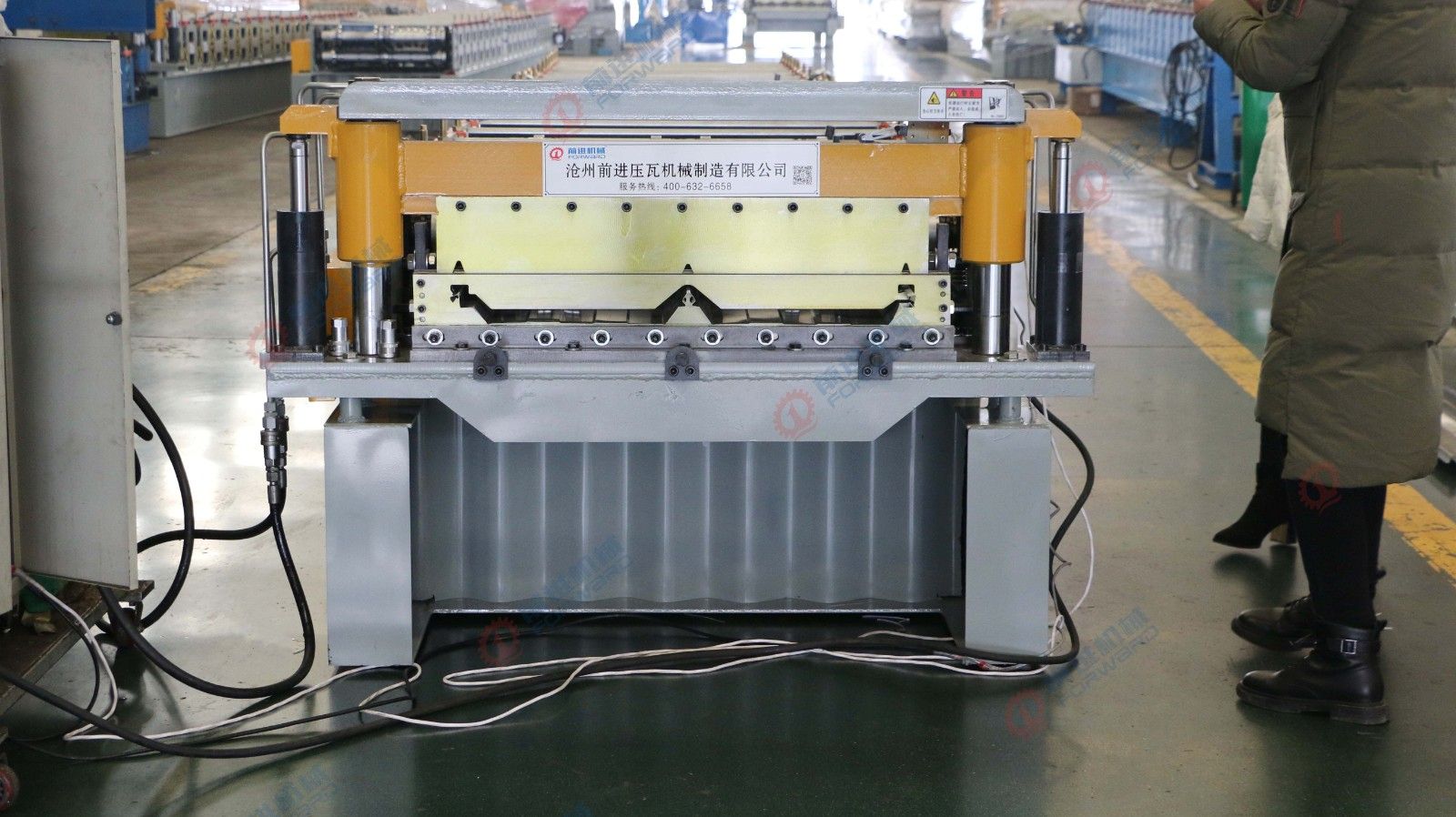

Machine Appearance

Main Components

The high-altitude roof tile roll forming machine can cooperate with the high-altitude lift to directly transport the color steel tiles to the top of the factory building. The lifting height exceeds 30 meters. The whole system is composed of general vehicle chassis, sub-frame, slewing system, lifting system, balancing system and special tile forming machine. It has been realized that the color steel tiles can be directly transported to the top of the factory building on site. It is suitable for large-span steel structure workshops and saves the cost of manual tile laying. The high-altitude lift tile forming machine integrates unwinding, tile pressing, hoisting, and transportation. On-site construction reduces the impact of the hoisting process on the quality of steel tiles.

Technical Specification

The high-altitude tile forming machine is a large-scale aerial tile-making equipment. It lifts the roofing machine to a certain height, and then carries out high-altitude tile pressing by directly laying tiles in the air. The whole process only needs to be controlled by remote control. It reduces the occurrence of tile damage and engineering accidents during the construction process, and this tile-making method also greatly increases the construction efficiency of the steel structure workshop, reduces the problem of tile damage, and greatly increases the safety of the construction process, making The entire establishment process is fast, safe and smooth, and the time is greatly reduced. If you can correctly analyze the causes of various failures, take effective and targeted preventive measures , It can effectively prevent mechanical failure and prolong the mechanical life of the high-altitude tile press.

Production Parameters