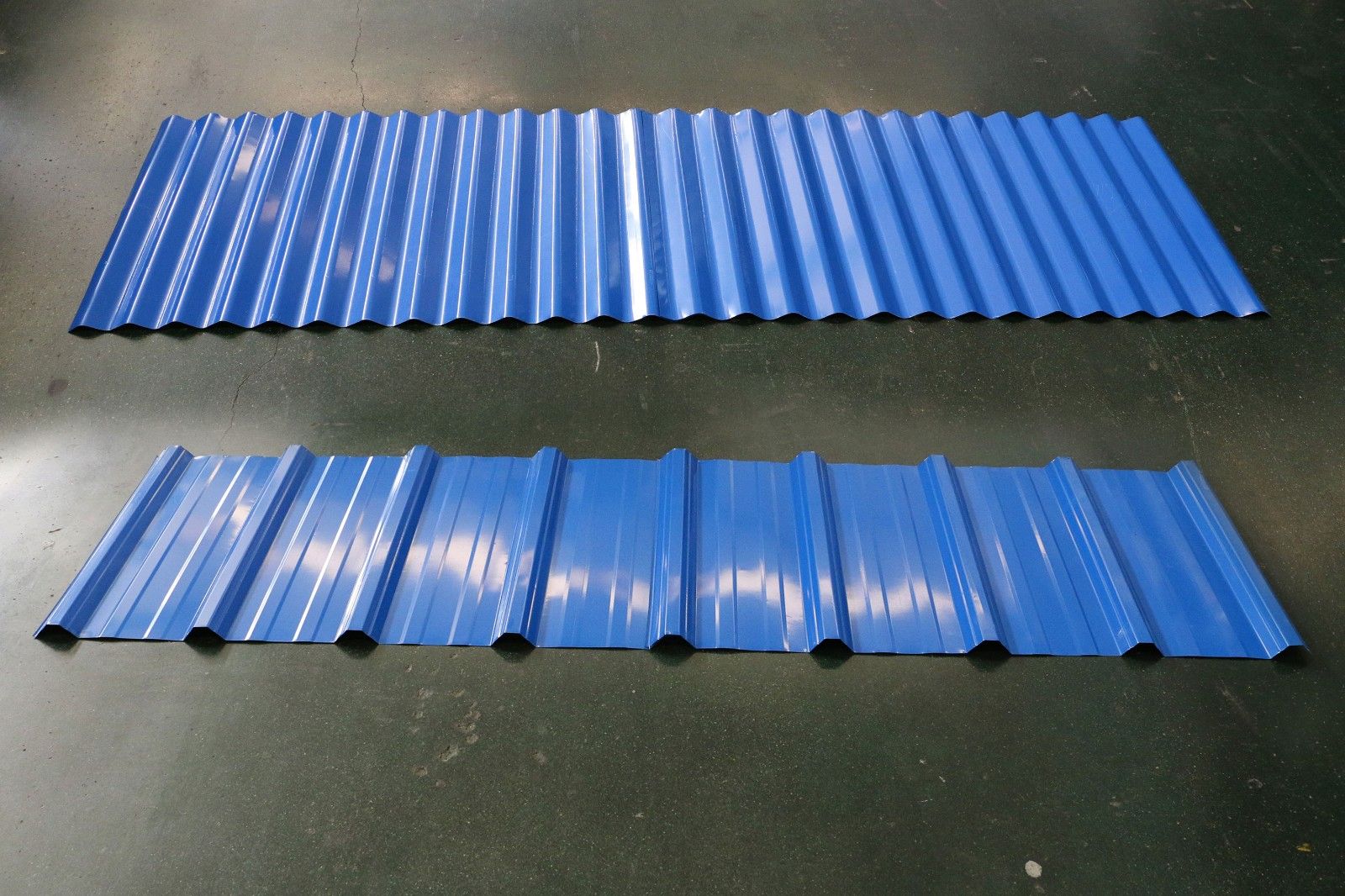

Double layer forming machines for roofing and cladding sheets , with the greatest advantage is one double layer machine can make two design sheets.

usually, one layer forming machine or single layer forming machine only make one roofing design.

Therefore, if customer has limited install space and required to make two roofing designs, double deck machine is best choose.

shall we introduce you difference between one layer machine and double layer machine?

one layer machine include manual decoiler, forming machine with post cut, hydraulic station, plc controller run out table.

double layer machine have additional set rollers and cut blade for another roofing design. that is , two sets rollers share with one machine base, motor , hydraulic station, plc controller and cut frame.

therefore, double layer forming machine only work one layer at one time.

Recently, double layer machine cut controlled by motor is adopted, it is good use in hot area, because, traditionally, hydraulic station give power to cut action, if in hot area, the oil in hydraulic station will very hot.

while motor control cut in hot area is good idea.

Attached forming machines are made to UAE, America, Mexico, central america, colombia…..

Your profiles will be designed to double layer machines and quoted accordingly.